Boundary conditions

Like all other calculation models, NetSim needs specific input data. These requirements are all quite simple and natural. A calculation model has to meet a number of hydraulic and thermal requirements before a problem is defined and can be resolved.

Fundamentally, the following conditions have to be met:

· Flow or power consumption must be specified at all nodes except for one.

· An absolute pressure must be specified.

· A differential pressure must be specified.

· The cooling or return temperature must be specified at all nodes with consumption.

· The temperature in the supply pipe must be specified at production plants (producers).

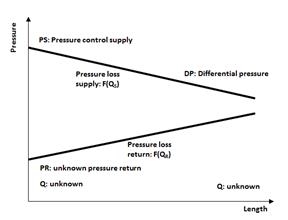

Pressure drop in a single pipe

The simplest possible system - one pipe and two nodes - is shown in the figure above. This system meets the requirements for both pressure and differential pressure and the flow being known at all nodes, except for one. The nodes in which the flow and pressure are stated is of no significance.

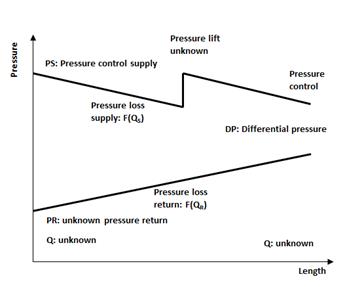

In some cases, more than one pressure check must be specified; for example, if a pressure increase or a pressure drop in a valve is to be calculated. In these cases, more than one pressure must be known, one for every ΔP to be calculated. The unknown pressure change must be positioned between the known absolute pressures in relation to the direction of flow of the liquid.

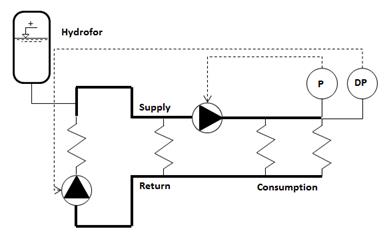

Model of a pipe network

provided with a pump controlled to find a set pressure at the end point

Model of a pipe network

provided with a pump controlled to find a set pressure at the end point

Pressure gradients for model defined in figure above

The two examples below show exceptions which may occur in respect of what was described above:

· If the unknown pressure P is set in a pipe which is part of a system containing ring connections.

· In a node, the known flow can be replaced by another known pressure. The flow is then calculated on the basis of the calculated pressure profiles.