Dimensioning

NetSim can be used for dimensioning pipes. The user can specify which of three criteria are to be used:

1. Maximum permitted velocity in the pipe.

2. Maximum permitted gradient in the pipe.

3. Dimension-dependent criterion where a velocity criterion is used if the diameter is less than a diameter specified by the user, and a pressure gradient criterion is used if the diameter is less than the diameter specified by the user.

It is possible to specify the criterion as a global criterion, i.e. it is used for all pipes to be dimensioned. It is also possible to assign individual criteria to the pipes.

NetSim uses dimensions from a pipe directory, which ensures that the criterion is not breached.

There is no limit on how many pipes can be dimensioned, but the number of pipe types to choose from is limited to 20 different types/dimensions. A name, internal diameter, roughness and heat loss factor are specified for every pipe type.

A pipe's diameter is dimensioned if the pipe's diameter is not defined from the outset. NetSim assigns a diameter to the pipe, which is chosen from the pipe types in the active directory. If the roughness of the pipe is not defined, the pipe's roughness is also selected.

The user must be aware that it is possible to define problems relating to pipe dimensioning which have no hydraulic solution. One example is a looped system. If the pipe to be dimensioned is part of a loop and two different pressure gradients are specified, a hydraulic solution does not necessarily exist. In cases such as this, NetSim will not arrive at a solution and the maximum number of iterations will be exceeded.

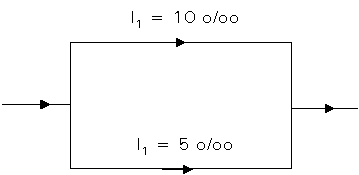

An insoluble dimensioning problem

In the example above, the user has to specify at least one of the dimensions.

Note that there may be combinations of dimensioning criteria, pipe lengths and reference pressure values in a model which has a hydraulic solution despite everything. In the example above, a solution can be found if the two pressure gradients and the two pipes are equal in size.